What is concrete shrinkage?

Concrete shrinkage is the decrease in length or volume of a concrete caused by changes in moisture content or chemical reactions. All concrete undergoes shrinkage, and there are four categories of shrinkage seen in concrete: Drying Shrinkage, Chemical Shrinkage, Plastic Shrinkage, and Autogenous Shrinkage.

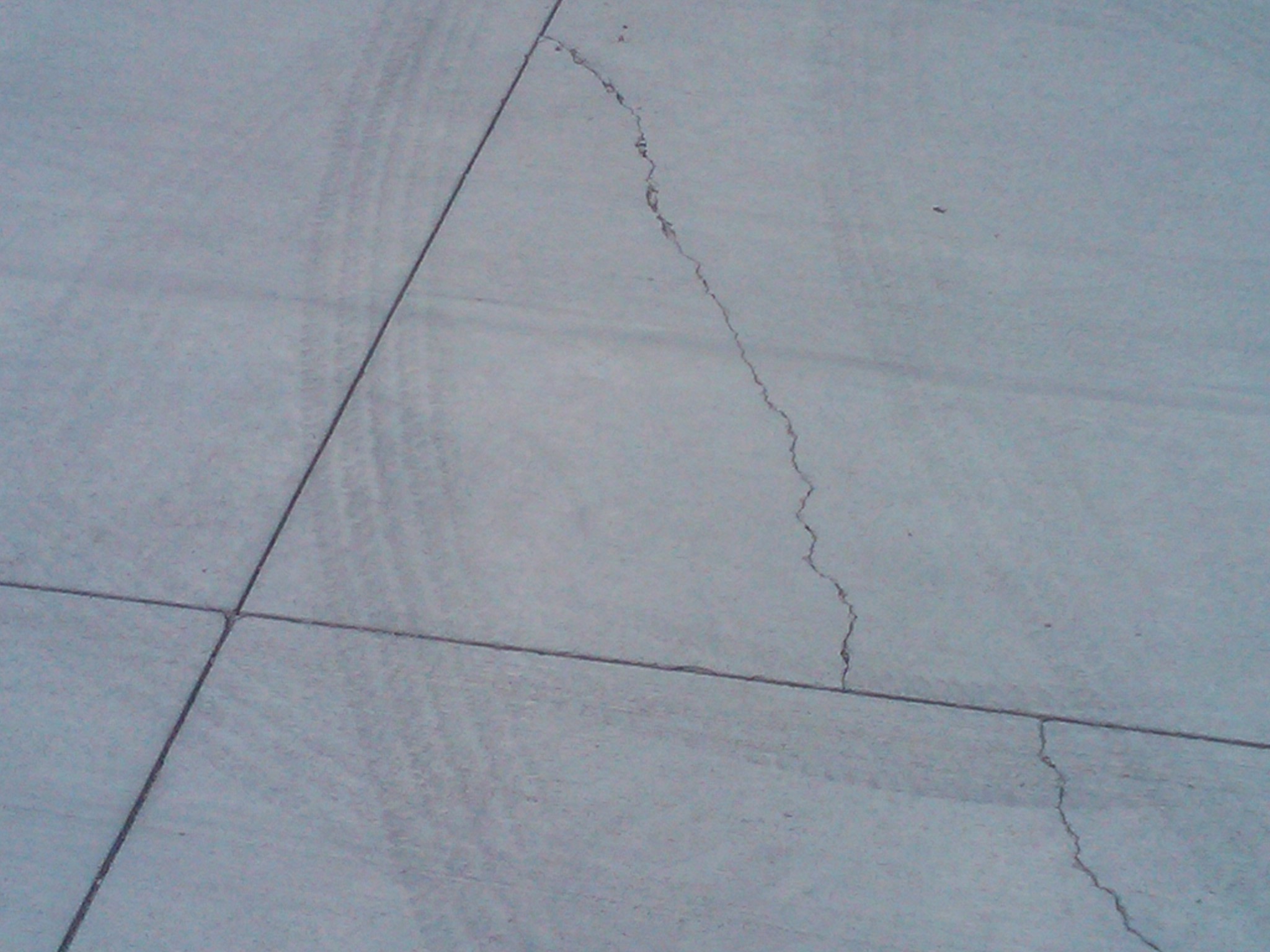

Drying shrinkage is the significant shrinkage mechanism in most concrete. Moisture lost during drying shrinkage is evaporated into the environment as the concrete dries out, and if not properly managed, it can lead to wide joint openings, cracking from internal stresses, and slab curling.

Common Misconception: Water-to-Cementitious Ratio

A common misconception when trying to limit drying shrinkage is that a low water-to-cementitious ratio (w/c must be specified to control shrinkage. It should be noted that water-to-cementitious ratio is a “ratio,” and has a numerator and a denominator with many combinations which will still meet the specified ratio. Table 1 illustrates this. Limiting water-to-cementitious ratio does not limit the shrinkage of a mix.

Table 1, Example combinations of 0.45 W/C

| Cement | Water |

| 500 | 225 |

| 600 | 270 |

| 700 | 315 |

| 800 | 360 |

| 900 | 405 |

| 1000 | 450 |

The Truth About Drying Shrinkage

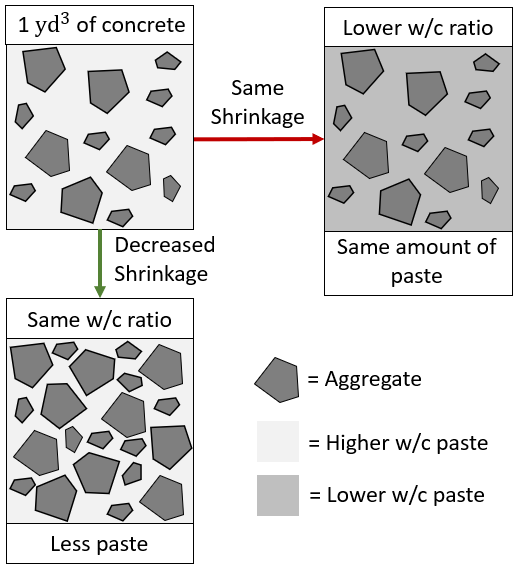

The two major components of concrete are aggregates and paste. Shrinkage occurs in the paste, and the aggregates are typically considered volume stable. This is why drying shrinkage is most-effectively managed by designing the volumetric ratio of paste-to-aggregate instead of the water-to-cementitious ratio.

The figure above illustrates that decreasing the water-to-cementitious ratio may have no impact on reducing shrinkage. However, shrinkage can be significantly reduced if the amount of paste is reduced.

Paste Content

Paste content can affect many properties of the concrete in both the plastic and hardened state. Sufficient paste is needed to help mix, place, and finish any concrete. The amount of paste content required to make a mix perform as needed will depend heavily on the aggregates in the mix. There are many ways to design mixtures to limit the paste content and maintain the performance of the mix. It should be recognized that specifying paste content or aggregates to be used will greatly limit the ability of the concrete designer to develop mixtures for the raw materials available.

Addressing Drying Shrinkage in Specifications

Water-to-cementitious ratio directly impacts properties related to concrete strength and durability, but it has less of an impact on shrinkage. If shrinkage is a concern, consider the use of a low shrinkage concrete or shrinkage compensating admixture. It is most effective to specify a maximum 28-day length change according to ASTM C157, “Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete.” At 28 days of age, the length change of a typical concrete due to shrinkage about 0.06 percent or greater. According to ACI 360, “Design of Slab on Grade,” the length change of low shrinkage mixtures are 0.052 percent or less. Specifications routinely require 28-day shrinkage to be below 0.04 percent to reduce the risk of shrinkage-related defects.

Keep in mind there are many aspects of concrete construction and specifying one property of the mix design is not sufficient to have a slab on grade or other structure perform as expected. Understanding the basic principles of concrete, such as shrinkage, and properly performing the many steps in the construction of concrete structures can go a long way toward completing a project on time and achieving the expected performance.

If you have any questions, please contact us.