Expanding the Boundaries of NDT: Digital Radiography and Computed Tomography

Services:

Markets:

Expanding the Boundaries of NDT: Digital Radiography and Computed Tomography

by Braun Intertec | August 19, 2025

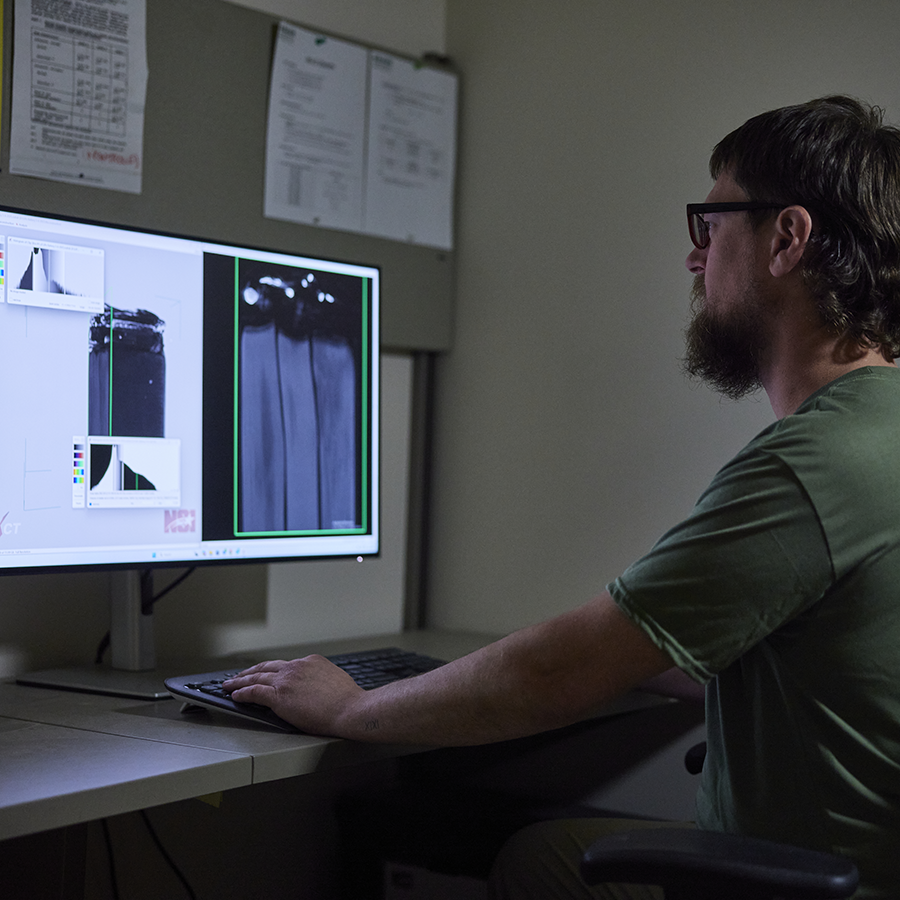

In 2025, Braun Intertec made significant investments to our nondestructive (NDT) testing capabilities with state-of-the-art Digital Radiography (DR) and Computed Tomography (CT) systems. We actively scan a wide range of components, from welds, castings, to complex aerospace and additive-manufactured parts. Whether you need a quick 2-D check or a precise 3-D reconstruction, our expanded capabilities are ready to meet the most demanding inspection challenges allowing us to deliver faster results, more detailed analysis, and greater insight for our clients.

Digital Radiography (DR) vs. Computed Tomography (CT): Choosing the Right Tool for the Job

In today’s fast-paced manufacturing and inspection environments, accurate, efficient, and detailed NDT has never been greater. Two of the most powerful imaging technologies available include Digital Radiography (DR) and Computed Tomography (CT).

Digital Radiography (DR): Fast, Versatile Imaging

Digital Radiography uses a digital detector to capture X-ray images instantly, eliminating the need for film processing. DR provides a 2D image of the part under inspection and can be performed in real-time or near real-time.

Key Benefits:

- Speed – Immediate image acquisition and review

- Portability – Adaptable to field or lab environments

- Lower Operating Costs – No film, chemicals, or extensive processing time

- Enhanced Image Processing – Digital manipulation tools for better defect visibility

Best Applications:

- Weld inspections

- Casting quality checks

- Corrosion monitoring in pipelines and structures

- Quick accept/reject screening for high-volume parts

Computed Tomography (CT): 3D Insight Into Internal Structures

Computed Tomography uses a series of X-ray images taken from multiple angles to create a 3D model of the part. This allows inspectors to virtually “slice” through the object for detailed internal visualization without cutting or destroying it.

Key Benefits:

- Full 3D Visualization – View internal and external geometry from any angle

- High Measurement Accuracy – Dimensional analysis down to microns

- Defect Characterization – Identify size, shape, and exact location of flaws

- Reverse Engineering – Generate CAD models from scanned data

Best Applications:

- Complex aerospace and medical components

- Additive manufactured (3D printed) parts

- Failure analysis and root cause investigations

- Precision dimensional verification against CAD models

Which Should You Choose?

While both DR and CT are powerful tools, the right choice depends on your inspection goal:

- DR for cost-effective 2D imaging for high-volume or routine inspections.

- CT for high-resolution 3D data, complex defect analysis, or dimensional verification.

In some cases, a hybrid approach, using DR for initial screening and CT for in-depth analysis, can provide the best balance of efficiency and detail.

The Bottom Line

Digital Radiography and Computed Tomography each play a critical role in modern NDT. Selecting the right method aligns the inspection approach with your project’s objectives, budget, and timeline. Whether it’s the rapid throughput of DR or the in-depth 3D insight of CT, both capabilities meet the most demanding quality and safety standards in the industry. With both DR and CT expertise under one roof, our team works at the intersection of natural and built environments – combining science, technology, and engineering to deliver precise, reliable results.

Services:

Markets: