Note: This project won a 2021 ACEC Engineering Excellence Awards Grand Award and was named one of the top 16 projects of the year. This project also received an ACEC Engineering Excellence awards Grand Award from the Minnesota chapter of ACEC.

For the last 10 years, Solidia Technologies has been developing a patented cement technology which will lower carbon emissions during the manufacturing process and truly consume carbon as it cures. However, the problem with this new form of cement, as opposed to traditional cements currently in use, is there are no ASTM tests and specifications developed to establish its strength and performance. ASTM standards are what enable a concrete product to be incorporated into a construction project with confidence the concrete product’s performance will meet the requirement of the structure.

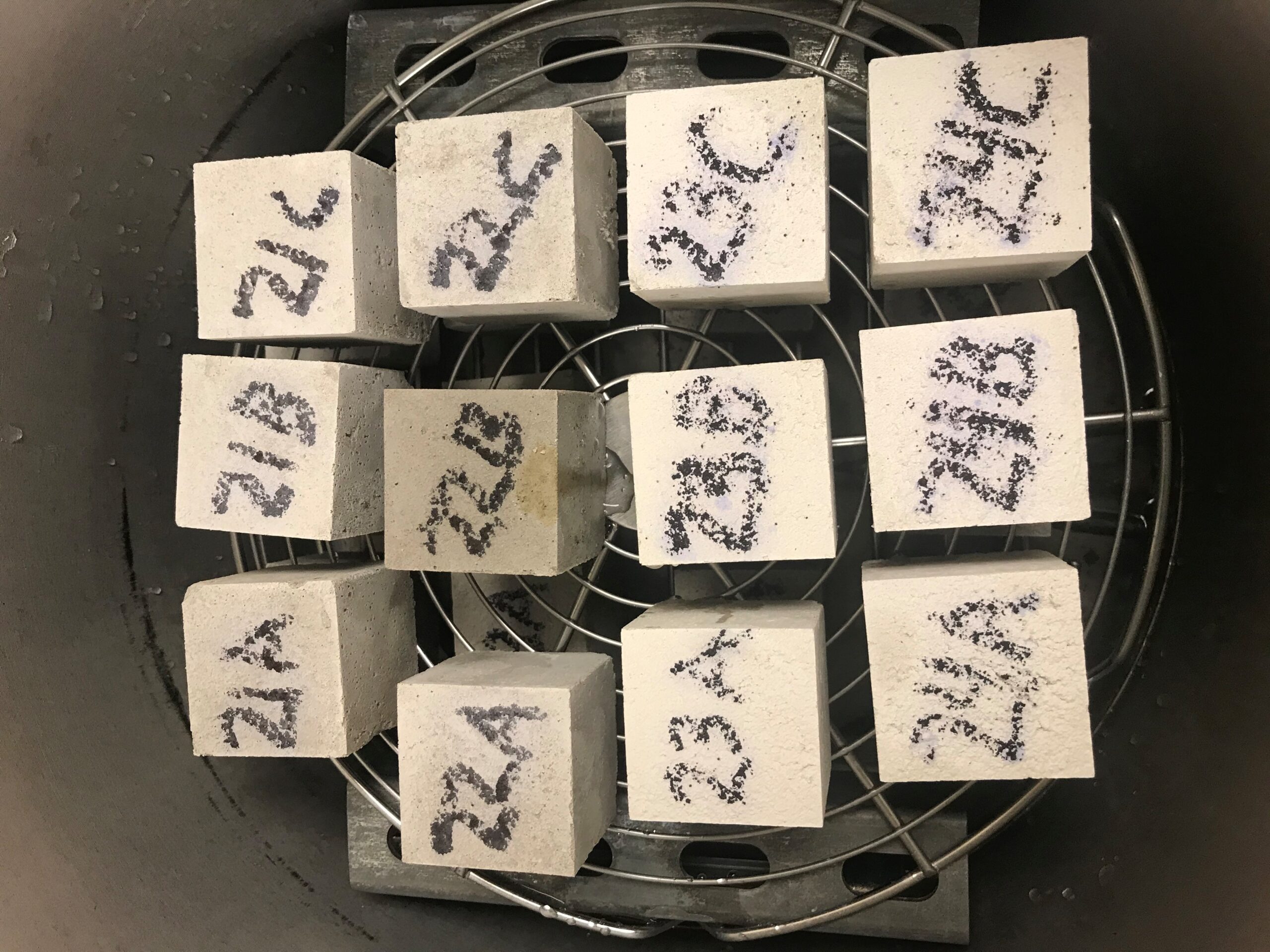

Braun Intertec was asked by Solidia Technologies to provide validation for the standard test method for compressive strength of mortar cubes with cement that hardens by carbonation as well as specification targets for cement that hardens by carbonation. Both the standard test method and specification targets would ultimately be submitted to ASTM for balloting and acceptance.

Braun Intertec presented their data and analysis with Solidia Technologies at ASTM meetings and then submitted that data and analysis along with the two new ASTM standards to balloting by the ASTM body who agrees to new standards and specifications. The proposed ASTM standards, tested and validated by Braun Intertec, have been balloted twice, received ballots back and are preparing to re-ballot the standards soon.

Low-Emission Supplementary Cementitious Material Evaluation

The second phase of this project required the validation of a new manufactured Supplementary Cementitious Material (SCM) or “pozzolan” which forms by pre-carbonating the cement manufactured by Solidia Technologies. This newly discovered SCM’s chemical reaction not only lowers the carbon footprint of concrete but also sequesters carbon during the manufacturing process. Solidia Technologies’ discovery of this new pozzolan is also noteworthy because every year in the United States sources for fly ash (a byproduct of coal-fired electricity production), another kind of pozzolan vital to types of concrete, are declining.

As a pozzolan, fly ash does more than simply reduce the carbon footprint of concrete. In fact, it helps improve the performance and durability of concrete. As a result of these performance-enhancing characteristics, entities like departments of transportation specifically call for fly ash in their concrete to meet performance specifications detailed in their project plans.

With fly ash production declining and the demand for high-performance concrete increasing, the supply chain shortage of valid materials for concrete starts to snowball. This shortage opened a window in the market for the development of a novel, green pozzolan. However, novel materials for concrete are difficult to market successfully without a record of proven durability to gain wide acceptance within the construction industry.

Measuring performance and durability with proven, easy-to-understand, precise standards

To overcome the hurdle of market acceptance and proven durability, Braun Intertec was tasked to take various versions of the Solidia Technologies SCM and test it in concrete. Braun Intertec performed trial batching in the lab, i.e. performance testing, to prove its performance in hardened concrete and that it could—and would—be an excellent pozzolan replacement for materials like fly ash.

The concrete industry has not experienced meaningful change since the 1940’s. What sets the Braun Intertec ASTM standard development, and subsequent SCM testing, apart from other attempts at innovation in the concrete market, is that the standards Braun Intertec worked with Solidia Technologies to establish will make it easier for the construction industry to adopt new technology. This is because it now has proven, easy-to-understand, precise standards to measure its performance and durability.

This suite of tests and ASTM standards development provides standards for laboratories to follow for any company who may bring a concrete product that is hardened by carbonation to market and proves the efficacy of their product to external bodies. This development also provides the engineering, construction, and concrete industry with enough supporting data to move quickly and confidently toward integrating a novel green concrete technology into their projects.